Laser cutting has become a versatile and creative method for producing intricate designs on a variety of materials, and with paper, the possibilities are endless.

In this comprehensive guide, we'll take an in-depth look at laser cut paper, explore the types of paper suitable for laser cutting technology, and provide you with a step-by-step guide. Whether you're an experienced craftsman or new to laser cutting, we will answer common questions for you to ensure your project is both successful and safe.

In this article:

Part 1: Can You Laser Cut Paper?

Yes, laser cutting is a popular and effective method for cutting paper. Laser cutting works by directing a high-powered laser beam through a computer-controlled machine that follows a specific design. The laser beam can cut through or engrave the paper, creating precise and intricate patterns.

When laser cutting paper, it's essential to use the appropriate settings to ensure a clean and accurate cut without burning or scorching the paper. The settings may vary depending on the type and thickness of the paper being used.

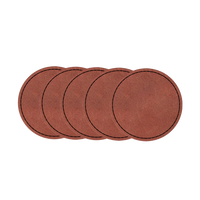

Many creative projects, such as paper art, invitations, and packaging, utilize laser cutting for its precision and versatility. If you're considering laser cutting paper, it's advisable to test the settings on a small piece of the same paper to determine the optimal parameters for your specific material.

Part 2: Which Types of Paper are Suitable for Laser Cutting?

Laser cutting is compatible with various types of paper, but some are more suitable than others. The ideal paper for laser cutting is usually thin and doesn't contain materials that could produce harmful fumes when burned. Here are some types of paper commonly used for laser cutting:

- Cardstock: A thicker and sturdier paper, cardstock is a popular choice for laser cutting. It comes in various colors and finishes, making it versatile for different projects.

- Bristol Board: Bristol board is a heavyweight paper with a smooth surface. It's often used for applications where a thicker material is desired.

- Kraft Paper: This brown paper is known for its strength and durability. It can be laser cut for a rustic or natural look.

- Watercolor Paper: Watercolor paper is thicker and has a textured surface. It can be laser cut for artistic projects and customized stationery.

- Textured Paper: Papers with interesting textures can add a unique visual element to laser-cut designs. However, very textured papers may require adjustments to laser settings.

- Parchment Paper: Thin and semi-translucent, parchment paper can be laser cut for delicate and decorative applications.

- Paperboard: Similar to cardboard but thinner, paperboard is suitable for laser cutting and is often used for packaging prototypes, cards, and crafts.

Part 3: How to Laser Cut Paper at Home - Step by Step Guide

Laser cutting paper at home can be a creative and rewarding DIY project. Here's a step-by-step guide to help you laser cut paper at home:

Step 1. Acquire a Laser Cutter:

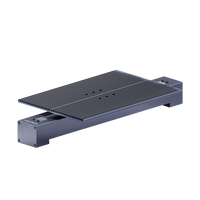

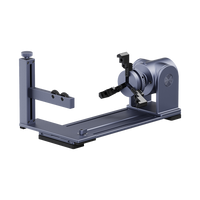

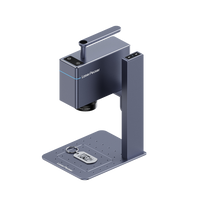

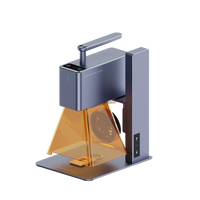

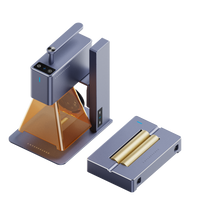

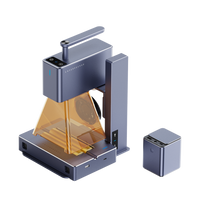

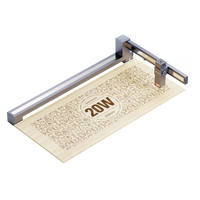

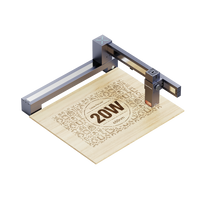

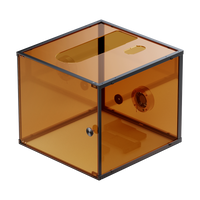

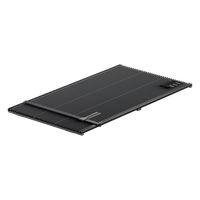

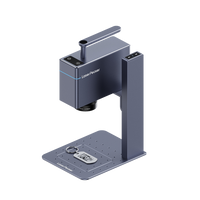

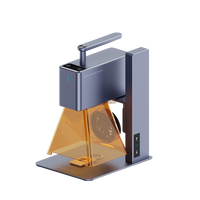

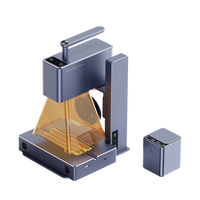

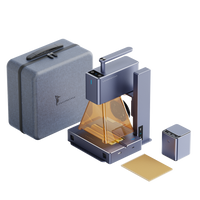

There are various types and models available, ranging from small desktop units to larger, more powerful machines. Ensure that the laser cutter is suitable for paper cutting. We recommend LaserPecker LX1 Foldable and Compact Laser Cutting Machine. You can laser cut paper with it easily at home.

Step 2. Choose the Right Paper:

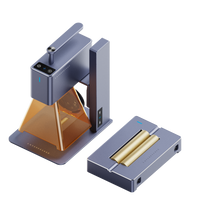

Select a type of paper suitable for laser cutting, such as cardstock, Bristol board, or another paper type that meets your project requirements. Consider the thickness and texture of the paper.

Step 3. Design Your Project:

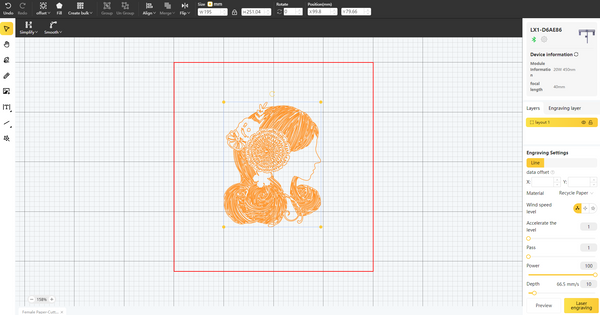

Use LaserPecker Design Space software to create or import the design you want to cut. Ensure that the dimensions match the size of your paper.

Step 4. Set Up the Laser Cutter:

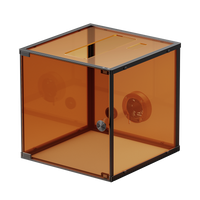

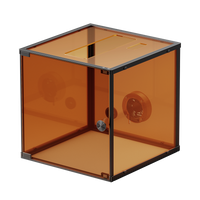

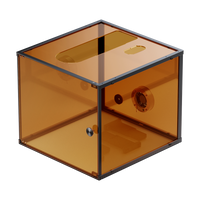

Always follow safety guidelines provided by the laser cutter's manufacturer. Use protective gear like laser safety glasses and ensure proper ventilation in the workspace.

Power on the laser cutter and ensure it's properly calibrated. Set the focus and adjust the laser power and speed settings based on the type and thickness of the paper. Consult the laser cutter's manual for specific instructions.

Step 5. Prepare the Material:

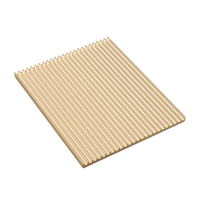

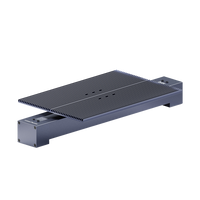

Secure the paper onto the cutting bed of the laser cutter using masking tape or other non-permanent adhesive. Make sure the paper lies flat and is free from wrinkles.

Step 6. Test Cut:

Before cutting your entire design, perform a test cut on a small scrap piece of the same paper to ensure the laser settings are correct. Make adjustments as needed to achieve the desired result.

Step 7. Load Your Design:

Load your design file into the laser cutter's software. Ensure that the settings are correctly configured for the chosen paper type.

Step 8. Start the Laser Cutting Process:

Initiate the cutting process through the laser cutter's control panel or software. Monitor the cutting progress to ensure everything is going smoothly.

Step 9. Remove the Cut Pieces:

Once the laser cutting is complete, carefully remove the cut pieces from the cutting bed. Be gentle, especially with delicate or intricate designs.

Step 10. Finishing Touches:

Depending on your project, you may need to remove any remaining burnt edges or residue. This can be done using a soft brush or compressed air.

For more info, please check our LaserPecker Craftzone. More projects are waiting for you to explore!

Part 4: FAQs about Laser Cut Paper

1. Can any type of paper be laser cut?

While many types of paper can be laser cut, it's essential to choose papers without coatings or materials that could produce harmful fumes. Common choices include cardstock, Bristol board, kraft paper, watercolor paper, and parchment paper.

2. Can I use a regular printer paper for laser cutting?

Laser cutting regular printer paper is possible, but it may not produce as clean and precise results as thicker papers. Thinner paper may curl or warp during the cutting process.

3. What thickness of paper is suitable for laser cutting?

Laser cutters can handle a range of paper thicknesses, but typically, papers in the range of 80 to 150 gsm (grams per square meter) work well. Thicker papers may require adjustments to laser settings.

4. Can laser cutting burn or scorch paper?

Yes, if the laser power or speed settings are too high, it can cause burning or scorching on the edges of the paper. It's important to perform test cuts and adjust settings accordingly.

5. How do I prevent paper from catching fire during laser cutting?

Adequate ventilation and proper laser settings can help prevent paper from catching fire. Ensuring the laser power is set appropriately for the paper thickness is crucial to avoid excessive heat.

6. Are there any safety precautions when laser cutting paper?

Yes, always follow safety guidelines provided by the laser cutter's manufacturer. Wear appropriate protective gear, such as safety glasses, and ensure proper ventilation in the workspace to mitigate the risk of inhaling fumes.

7. Can I engrave on paper using a laser cutter?

Yes, laser cutters can engrave intricate designs onto paper surfaces. Adjustments to laser power and speed settings are necessary to achieve the desired engraving depth without cutting through the paper.

8. Can I use a home laser cutter for paper projects?

Yes, there are desktop laser cutters suitable for home use, such as LaserPecker LX1. Ensure that the laser cutter you choose is compatible with paper cutting and follow the manufacturer's guidelines for safety and usage.

9. Can I reuse the same piece of paper for multiple laser cuts?

It's possible to reuse paper if the laser cutting process doesn't cause significant damage. However, for optimal results, it's recommended to use a fresh, flat piece of paper for each cutting session.

10. Can laser-cut paper be used for 3D projects?

Yes, laser-cut paper can be used for 3D projects by scoring and folding the cut pieces. This technique allows you to create intricate and detailed 3D structures.